概述

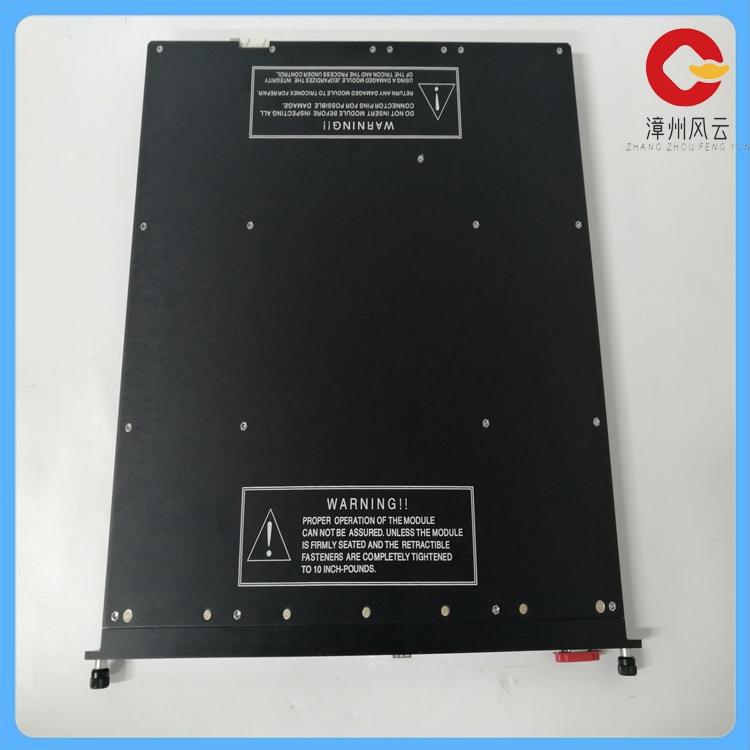

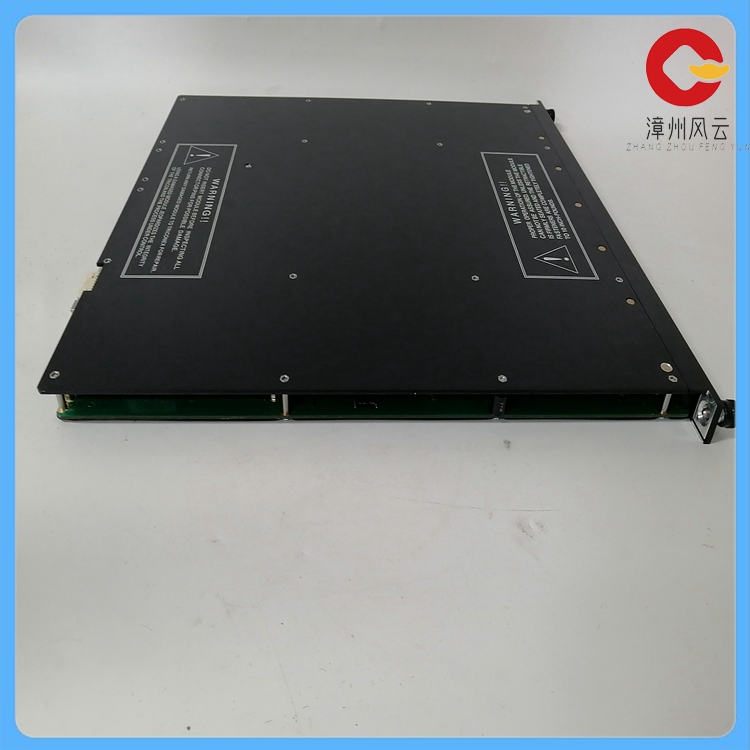

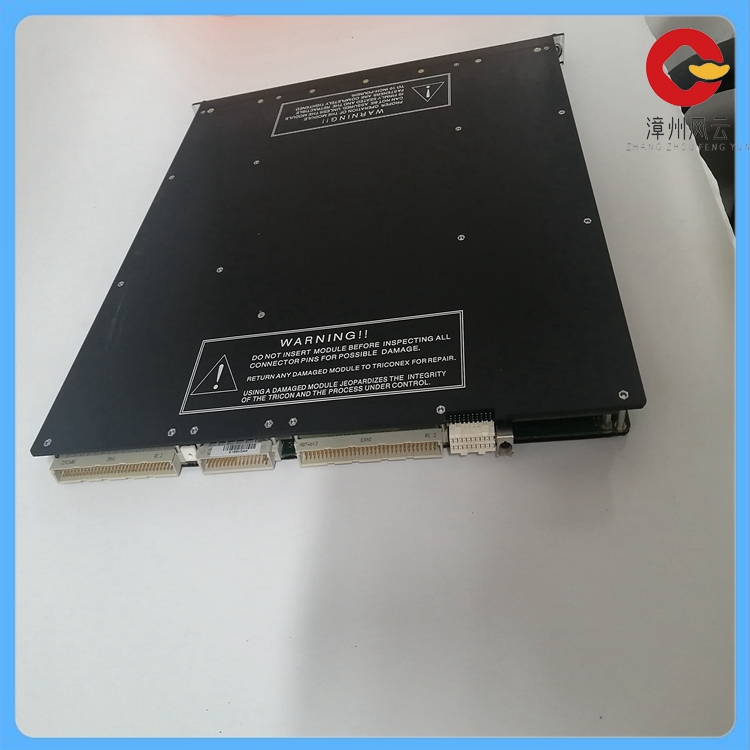

基本细节:TRICONEX 3009X 3009增强型主处理器(UMP)模块

TRICONEX 3009增强型主处理器(UMP)模块是一种可编程、容错的过程控制技术,具有以下特点:三模块冗余结构(TMR)由三个相同的子电路组成,每个子电路都具有独立的控制权。同时,专门的硬件/软件架构用于“对输入和输出进行投票”。能够承受恶劣的工业环境,安装可以现场进行,模块化级别的安装和维护可以在线进行,不干扰现场布线。支持多达18 /0模块(模拟和数字)和可选的通信模块。通信模块可以连接到MODBUS主机和辅助主机,或连接到Foxboro和honeywell分布式控制系统(DCS)的点对点网络,其他TRICON设备和TcP/pnetwork上的外部主机。

它可以支持距离主机最远12公里的远程I/O模块

使用基于Windows NT系统的编程软件开发和调试控制程序。输入输出模块具有智能化功能,减少了主处理器的工作量,每个10模块有3个微处理器。输入模块的微处理器负责过滤和修复输入数据,并诊断模块上的硬件故障。输出模块的微处理器提供输出数据的投票信息。并通过输出的反馈回路电压来检验输出状态的有效性。并能诊断励磁电路的问题

提供全面的在线诊断和修复功能

在TRICON启动和运行过程中,无需中断控制过程即可进行例行维护。提供0个模块的“热备”支持,可用于某些无法及时提供服务的紧急情况

MP3009X:任务的一个临时存储位置,在任务运行之前读取任务变量,并在任务完成后再次写入这些变量。这些变量被标记为@字符。

处理信息通知用户关于自由职业者系统中的干扰和具体状态的变化。可以区分系统消息、故障消息、交换机消息、提示消息和提示消息。根据消息类型对流程的重要性和优先级级别进一步细分。

这是一个主处置惩罚器和通讯模块的拉拢,通常用于产业自动化和安全相干的运用范畴。以下是能够的产物运用范畴:

安全体系: Triconex产物通常用于产业历程中的安全体系,比方煤油和天然气行业,以保证装备和历程的安全性。

历程掌握: 在产业临盆中,Triconex主处置惩罚器能够用于掌握和监控症结的临盆历程,保证临盆的稳定性和高效性。

煤油和天然气: 在油气临盆和处置惩罚中,Triconex体系能够用于伤害和掌握症结的装备,保证临盆历程的安全性和可靠性。

电力行业: 用于电力厂的安全体系,保证电力装备和历程的安全运转。

化工产业: 在化工临盆中,Triconex体系能够用于伤害装备、职员和情况安全。

核能产业: 在核电站和相干举措措施中,Triconex的体系能够用于伤害和监控症结的核能历程。

陆地产业: 在陆地和船舶行业中,Triconex体系能够用于安全和掌握体系,保证船舶和海上举措措施的安全性。

summarize

Basic details :TRICONEX 3009X 3009 Enhanced Main Processor (UMP) module

The TRICONEX 3009 Enhanced Main Processor (UMP) module is a programmable, fault-tolerant process control technology with the following features: A three-module redundant architecture (TMR) consists of three identical subcircuits, each with independent control. At the same time, specialized hardware/software architectures are used to "vote on inputs and outputs." It can withstand harsh industrial environments, installation can be carried out on-site, and modular level installation and maintenance can be carried out online without interfering with on-site wiring. Supports up to 18/0 modules (analog and digital) and optional communication modules. Communication modules can be connected to MODBUS hosts and secondary hosts, or to peer-to-peer networks of Foxboro and honeywell Distributed Control Systems (DCS), other TRICON devices, and external hosts on TcP/pnetwork.

It can support remote I/O modules up to 12 km from the host

Develop and debug control programs using programming software based on Windows NT systems. The input and output modules have intelligent functions, reducing the workload of the main processor, and each 10 modules has 3 microprocessors. The input module's microprocessor is responsible for filtering and repairing the input data and diagnosing hardware failures on the module. The microprocessor of the output module provides voting information for the output data. The validity of the output state is tested by the output feedback loop voltage. And can diagnose the problem of excitation circuit

Provides comprehensive online diagnostic and repair capabilities

Routine maintenance can be performed without interrupting the control process while TRICON is up and running. Provides "hot spare" support of 0 modules, which can be used for some emergency situations where services cannot be provided in time

MP3009X: A temporary storage location for tasks that reads task variables before the task runs and writes them again after the task is completed. These variables are marked as @ characters.

Processing information notifies users about disturbances and specific status changes in the freelancer system. You can distinguish system messages, fault messages, switch messages, prompt messages, and prompt messages. Further segmentation based on the importance and priority level of the message type to the process.

This is a co-location of the main disposal penalizer and communication module, commonly used in industrial automation and security related applications. The following are possible product applications:

Safety Systems: Triconex products are commonly used in industrial process safety systems, such as in the kerosene and natural gas industries, to ensure the safety of equipment and processes.

Process control: In industrial delivery, the Triconex master disposal punisher can be used to master and monitor the delivery process of the crux, ensuring the stability and efficiency of the delivery.

Kerosene and natural gas: The Triconex system can be used to damage and control the equipment during oil and gas delivery and disposal, ensuring the safety and reliability of the delivery process.

Power industry: Safety system for power plants to ensure the safe operation of power equipment and processes.

Chemical Industry: The Triconex system can be used to harm equipment, personnel and situation safety in chemical production plants.

Nuclear Energy Industry: In nuclear power plants and related initiatives, Triconex's systems can be used to harm and monitor the critical nuclear process.

Land Industry: In the land and Marine industry, the Triconex system can be used for safety and control systems to ensure the safety of ships and maritime initiatives.

| WOODWARD | 9907-164 |

| A-B | 1394C-SJT22-A |

| Siemens | 6ES7656-6CL33-1BF0 |

| WOODWARD | 9907-167 |

| FOXBORO | H92904CC0500 |

| WOODWARD | 8200-1312 |

| ABB | 5SHY4045L0004 3BHB021400R0002 |

| ABB | PM866AKO2 |

| FOXBORO | PO973LN SSA-G8018-0652 |

| 安川 | CLSR-33-N2CE-1 |

| FOXBORO | H929049B0500 |

| ABB | PFCL201C 2OKN |

| AMAT | AX8200A 0190-09437 |

| ABB | 5SHY4045L0006 3BHB030310R0001 |

| ABB | PM866K02 |

| ABB | PM645B |

| MEI | 1007-0016 |

| ABB | PM866AK02 |

| HP | HP 5517B |

| ABB | PFTL201C 10KN 3BSE007913R10 |

| ZYGO | 8070-0279-01 |

| ZYGO | 7702 |

| ABB | PFSK151 |

| ABB | PFSK152 |

| ABB | GVC736CE101 3BHB045647R0001 |

| GE | IC698CRE040 |

| WOODWARD | 8200-1302 |

| ABB | PM865K02 |