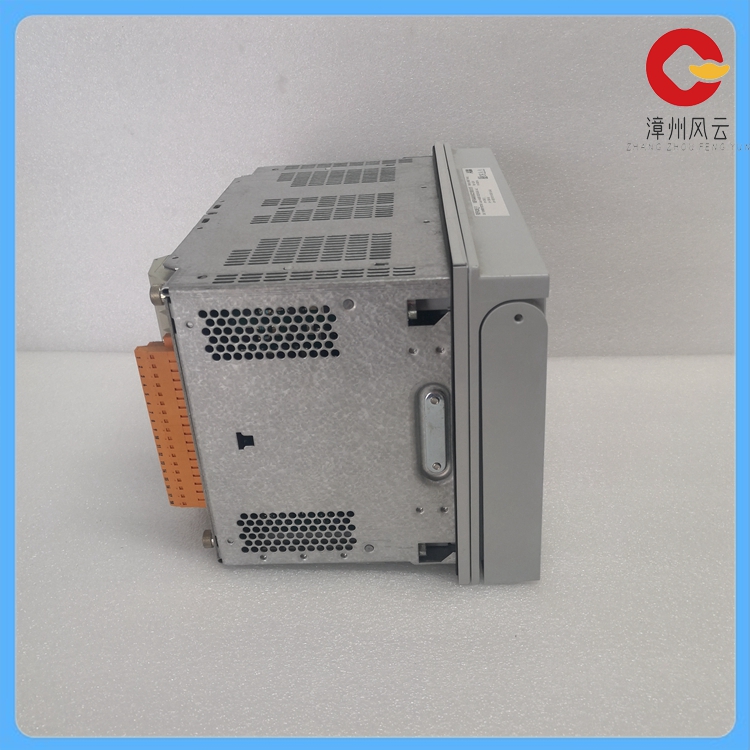

REF620E F NBFNAANNNCC1BNN1XFABB

电动机长时刻超载运转,绕组温升将超过其答应值,构成绝缘材料变脆、寿数缩短,严峻时还会使电动机损坏,过载电流越大,到达答应温升的时刻就越短,常用的长时刻过载维护元件是热继电器。热继电器不能兼作短路维护,由于发生短路时,它可能还来不及动作就已对电器设备构成损坏了。据统计,因断相运转而烧坏电动机的台数,在有些单位竟多达损坏电机总台数的80%以上,所以电动机应该有断相维护的环节,也就是说要选用带断相维护功用的热继电器。

矢量操控是经过矢量坐标电路操控电动机定子电流的巨细和相位,以到达对电动机在d、9、0坐标轴系中的励磁电流和转矩电流分别进行操控,从而到达操控电动机转矩的意图。经过操控各矢量的效果次序和时刻以及零矢量的效果时刻,又能够构成各种PWM波,到达各种不同的操控意图。例如构成开关次数最少的PWM波以削减开关损耗。目前在变频器中实践应用的矢量操控方法主要有基于转差频率操控的矢量操控方法和无速度传感器的矢量操控方法两种。

主要优势

集成在一台继电维护装置中的维护、操控、监测和管理为公共和工业配电系统提供了紧凑和通用的方案

具有广泛的维护和操控功用,能够用传感器或传统的 CT、PT

·功用的可扩展性和广泛的应用性,使用户可轻松定制配置应用程序以满意具体要求

快速安装和测验的可插拔式设计

带单线图显示的大液晶屏,可经过本地或易于衔接和浏览的 HMI来访问

周到的产品全寿数周期服务

REF620E F NBFNAANNNCC1BNN1XFABB

The electric length is always overloaded, the winding temperature rise will exceed its allowable value, the insulation material becomes brittle, the life is shortened, and the motor will be damaged when severe, the greater the overload current, the shorter the time to reach the allowable temperature rise, the commonly used long-term overload maintenance component is the thermal relay. Thermal relays can not double as short circuit maintenance, because when short circuit occurs, it may not have time to act on the electrical equipment has been damaged. According to statistics, the number of motors burned out due to phase break operation, in some units as much as 80% of the total number of damaged motors, so the motor should have a phase break maintenance link, that is, to choose a thermal relay with phase break maintenance function.

Vector control is to control the size and phase of the stator current of the motor through the vector coordinate circuit, so as to control the excitation current and torque current of the motor in the d, 9, 0 axis system respectively, so as to achieve the intention of controlling the motor torque. After controlling the effect order and time of each vector and the effect time of zero vector, it can form a variety of PWM waves to reach a variety of different control intentions. For example, PWM waves that constitute the fewest switching times are used to reduce switching losses. At present, there are two vector control methods which are based on slip frequency control and velocity sensorless vector control in frequency converter.

Major advantage

Maintenance, control, monitoring and management integrated in a single relay maintenance unit provides a compact and versatile solution for public and industrial distribution systems

Has a wide range of maintenance and control functions, can use sensors or traditional CT, PT

The extensibility and wide applicability of the function make it easy for users to customize and configure the application to meet specific requirements

Pluggable design for quick installation and testing

Large LCD screen with single-line chart display, accessible locally or through an HMI that is easy to connect and navigate

Thoughtful product life cycle service

| ABB | PFTL101A 1.0KN |

| ABB | PFTL101A 0.5KN |

| ABB | PFEA113-65 3BSE028144R0065 |

| ABB | PP845 3BSE042235R1 |

| ICS TRIPLEX | T8451C |

| EATON | XV-440-10TVB-1-50 |

| ABB | 5SHY3545L0016 38HB020720R0002 |

| FOXBORO | P0973KJ |

| EMERSON | SE3008 KJ2005X1-MQ2 13P0072X082 |

| B&R | 8V1180.00-2ACOPOS |

| WOODWARD | 5466-409 |

| AMAT | 0760-01020 |

| ICS TRIPLEX | T8448 |

| ABB | 3BHB005243R0105 |

| ABB | 5SHX0660F0002 |