- 伺服电机

1.概念

伺服电机,按操控指令的要求、对功率进行扩大、变换与调控等处理,使驱动设备输出的力矩、速度和位置操控的十分灵敏便利。

因为它的“伺服”功能,因而它就被命名为伺服电机。其功能是将输入的电压操控信号转为轴上输出的角位移和角速度驱动操控对象。

伺服电机一般分为两大类:直流伺服电机、沟通伺服电机。

2.沟通伺服电机

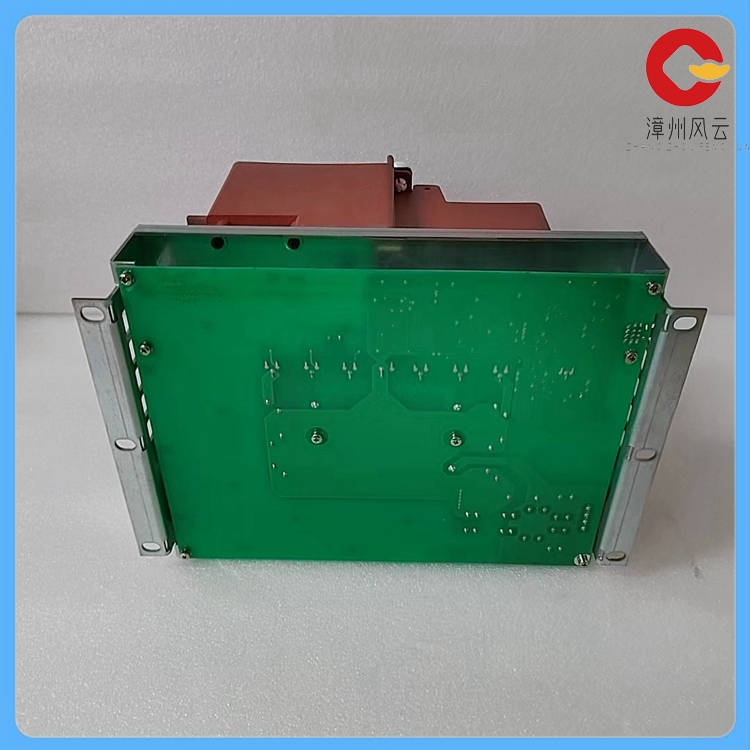

2.1 结构

2.2作业原理

沟通同服电机内部的转子是永磁铁,驱动器操控的UNN三相电形成电磁场,转子在此磁场的效果下滚动,一起电机自带的编码器反应信号给驱动器,驱动器根据反应值与目标值进行比较,调整转子滚动的视点,沟通同服电机在没有操控电压时,定子内只有励磁绕组产生的脉动磁场,转子静止不动,当有操控电压时,定子内便产生一个旋转磁场,转子沿旋转磁场的方向旋转,在负载恒定的情况下,电动机的转速随操控电压的巨细而改动,当操控电乐的相位相反时,伺服电动机将反转.扫播授术

当PLC投入运转后,其作业进程一般分为三个阶段,即输入采样、用户程序履行和输出刷新三个阶段。完成上述三个阶段称作一个扫描周期。在整个运转期间,PLC的CPU以一定的扫描速度重复履行上述三个阶段。

(-)输入采样阶段

在输入采样阶段,PLC以扫描方法顺次地读入所有输入状况和数据,并将它们存入!/0映象区中的相应得单元内。输入采样结束后,转入用户程序履行和输出刷新阶段。在这两个阶段中,即使输入状况和数据发生改动,1/0映象区中的相应单元的状况和数据也不会改动。因而,假如输入是脉冲信号,则该脉冲信号的宽度有必要大于一个扫描周期,才能确保在任何情况下,该输入均能被读入。

- Servo motor

1. Concept

Servo motor, according to the requirements of control instructions, the power is expanded, transformed and regulated, so that the torque, speed and position control of the output of the driving equipment is very sensitive and convenient.

Because of its "servo" function, it is named as a servo motor. Its function is to convert the input voltage control signal into the angular displacement and angular speed output on the axis to drive the control object.

Servo motors are generally divided into two categories: DC servo motors and communication servo motors.

2. Communication servo motor

2.1 Structure

2.2 Operating Principles

The rotor inside the motor is a permanent magnet, and the UNN three-phase electricity controlled by the driver forms an electromagnetic field. The rotor rolls under the effect of this magnetic field, and the encoder with the motor reacts signals to the driver. The driver compares the reaction value with the target value to adjust the rolling view point of the rotor. Only the pulsating magnetic field generated by the excitation winding in the stator, the rotor is stationary, when there is a control voltage, the stator will produce a rotating magnetic field, the rotor rotates along the direction of the rotating magnetic field, in the case of constant load, the motor speed with the size of the control voltage changes, when the phase of the control of the electric music is opposite, the servo motor will reverse. Scanning technique

When the PLC is put into operation, its operation process is generally divided into three stages, namely, input sampling, user program performance and output refresh three stages. Completing these three stages is called a scan cycle. During the entire operation period, the PLC's CPU repeats the above three stages at a certain scanning speed.

(-) Input sampling phase

In the input sampling phase, the PLC reads all input status and data in sequence by scanning method and stores them! Within the corresponding cell in the /0 mapping area. After the end of the input sampling, the user program implementation and output refresh phase. In both phases, even if the input state and data change, the state and data of the corresponding cell in the 1/0 map area will not change. Therefore, if the input is a pulse signal, the width of the pulse signal must be greater than one scan cycle to ensure that the input can be read in any case.

| ABB | PM511V08 3BSE011180R1 |

| HONEYWELL | FC-QPP-0002 |

| EMERSON | CE3008 |

| ABB | DSDP140B 57160001-ACX |

| EMERSON | VE3008 |

| ABB | PP885 3BSE069276R1 |

| WOODWARD | 8237-1246 |

| ABB | 57160001-ACX |

| NI | SCX1-1193 |

| GE | IC800SS1228RD2 |

| GE | IS420YDOAS1B |

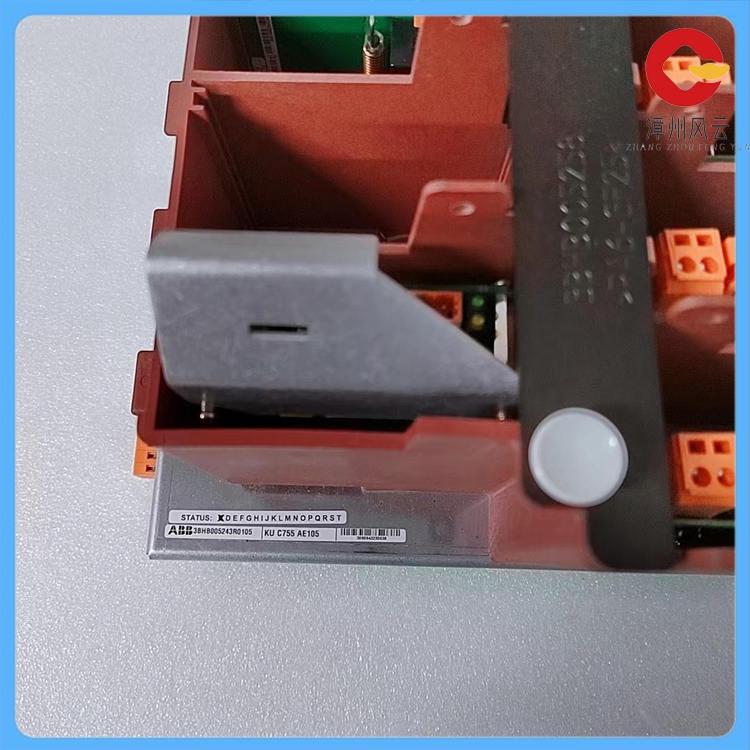

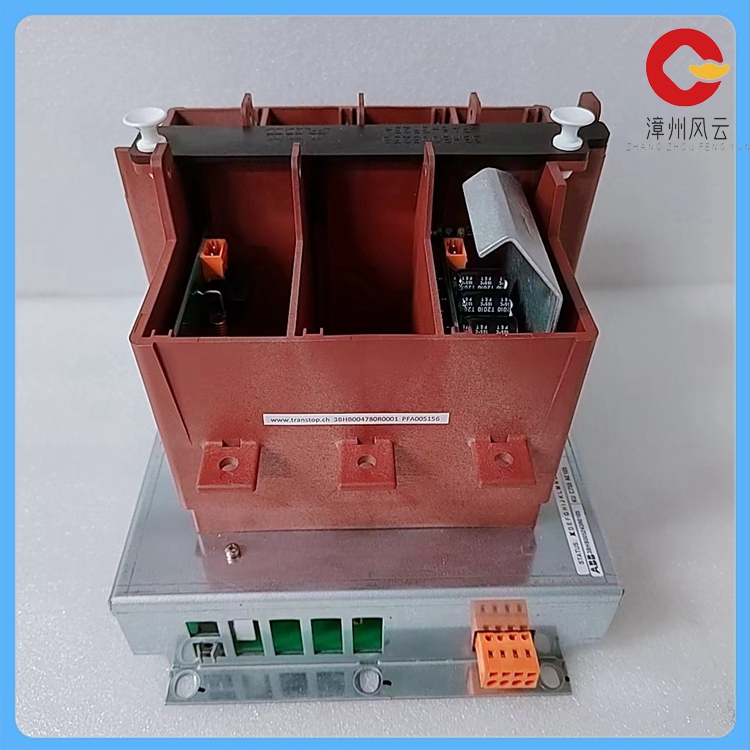

| ABB | KUC711AE01 3BHB004661R0001 |

| MOTOROLA | MVME5100 |

| ABB | SYN5202-0271 |

| NI | PXIE-8861 |

| MOTOROLA | MVME55006E-0161R |

| GE | VMIVME-4150 |

| LAM | 810-102361-222 |

| Baumuller | BUM61-20/30-54-B-0-12 |